Computing Bachelor of Science Degree - with Honours Project.

Prelude

In September 2000, at the grand age of 40, I re-entered the world of education with a view to returning to work as my children were growing up.When I was at school computers were not a part of the world in the way they are today; in the 1970's it was considered totally cool to have a brown commodore calculator, which performed various programmable calculations and displayed in red. I still have it today and it works perfectly!

Computing seemed a reasonable choice, so I enrolled at South Devon College along with all the other 16 year olds. In the beginning, I studied AS/A2 in Computing and was pleased when I achieved an 'A' for my efforts. It seemed appropriate to continue to a higher level, so I went on to study for a HND in Computing and passed with 86%.

After all this effort, my family and friends encouraged me to consider a degree. As South Devon College was affiliated with Plymouth University I discovered that my HND would count towards the first two years and I only needed to do the third and final year; this was an obvious choice for me to progress. As a mother and wife, legging it off around the country to a University of choice was not an option.

Plymouth University offered the opportunity to convert the HND to a degree and if I wanted to have the 'with Honours' then a suitable project had to be undertaken.

Project

I was advised to choose a project that had some 'wow' factor. I chose an interactive (physically allowed the examiner to partake in the experiment during the presentation); visually interesting (prototype vivarium in operation with real time graphs showing performance); use of stored information for performance checks.The project was formed of two parts, the first part was an interactive climate controlled simulation and the second part an Environment Climatic controlled system suitable for maintaining the habitat for exotic frogs held in captivity.

Information obtained through research on natural biome regions and climate controlled man-made biomes identified biome climatic characteristics and the technology used to recreate those characteristics. Further research on the requirements of amphibians and frogs in particular enabled the creation of the software and environment.

The first part created a prototype software using temperature, humidity and annual rainfall measurements of six natural biomes and through manipulating five synthetic control tools realised a hypothetical environment. Data was collected and transferred to a database, where it was used for reports on user preference.

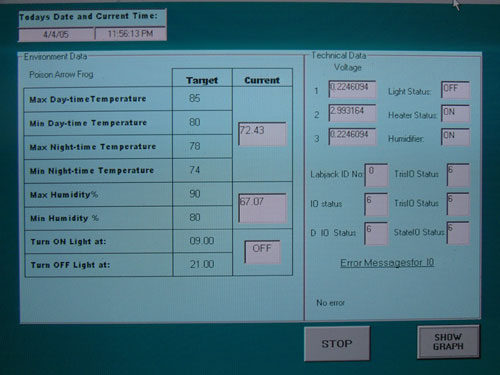

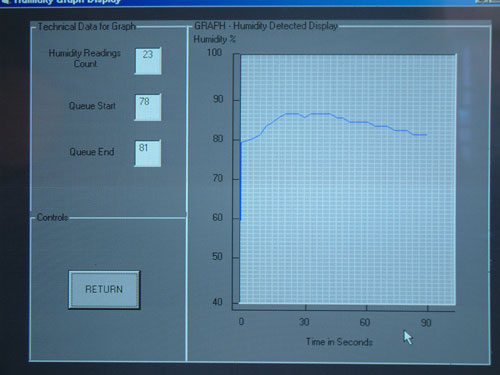

The second part designed and developed a prototype climate control system using temperature and humidity sensors to measure current conditions within a glass tank structure and use a microcontroller to control a switching mechanism for mains connected electric devices. The automated control of light, temperature and humidity was achieved. Continuous data collection was displayed realtime in the form of graphs and also used to produce charts portraying heating and humidity control performance.

The Sensoring Device

The TH-100 dual sensor was constructed in a plastic self-contained ventilated water resistant enclosure and supplied with 1.5 meters of cable. It was chosen for its ease of application and humidity range (from 0 to 100% as some frogs require a very high humidity environment) and humidity accuracy within +- 2%RH at 25C. The temperature range boasted 0 to 100C with accuracy +-0.9C at 25C.The sensor came pre-wired with instructions to connect four colour-coded wires to two analogue IO's, a ground and +5Voltage on a microcontroller. The ease of connection and disconnection made this device highly portable and suitable for the task of development.

The Microcontroller

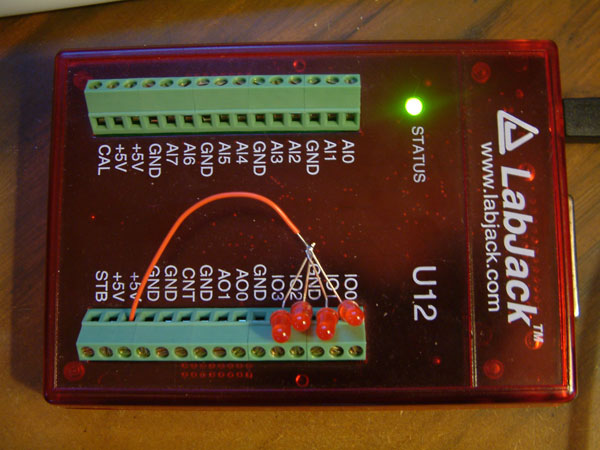

A LabJack U12 was the data acquisition and control device. The LabJack supported both analogue and digital inputs and outputs. The analogue IO was determined as necessary for the dual sensoring device and the digital IO was used to control the light, heater and humidifier devices. Connection to the microcontroller was via screw terminals and a DB-25 connector. The DB-25 connector facilitated direct interfacing with a switch relay board. The LabJack offered distinct advantages of portability, usability and came supplied with free software.Switch Relay System

A method was required that enabled control over switching mains connected electronic devices. Advice on the best course of action was obtained from the technicians in the Projects Lab. Three Zero Rated Solid State Relays(SSR)(PCB 1-phase ZS/IO type RP1a) provided the interface between the AC loads and the microcontroller. The relays acted as switches that allowed the electrical current to flow and turned on the lighting, heating and humidifier devices. The zero rated relays were chosen in preference for their ability to cope with spiking currents.Humidifier

The ultrasonic mini fogger was the most suitable for my purposes. The advantages are its size, cost, availability, as it would provide the high levels of humidity required. The main disadvantage was ensuring a water supply and devising a secure means of preventing frog access and water scalding.The fogger comes supplied with adapter 24 VAC/1.2A. This required a different connection to the switching device. A single trailing socket was used to control the mains supply to the Adapter. Direct wiring of fogger to relays was not feasible as the 24VAC electric load could not be handled by the relays.

An alternative Air spray could be easily constructed using a pump device such as a windscreen washer, tubing and fine nozzel to create a misting effect.

The Vivarium Program

The program was designed as an event driven program to initialise the conditions and parameters. Once initialised by the user the program was designed to run until stopped by the user.An OCX(OLE control extension) function was added to enable the Visual Basic program to access the supplied LabJack software. Timer functionality was incorporated to establish the frequency of data collection by the sensors and also to check the daylight hours parameters against the system clock time. A twelve-hour daylight period was programmed to operate between 9am and 9pm, outside of these hours the light function was switched off.

The microcontroller facilitated the data capture of temperature data from the sensor, which was received as a voltage. This data was converted to Celsius by applying a gain value supplied by Audon Electronics TH-100 specification sheet. This value was then converted to Fahrenheit for the output display.The humidity sensor data was also received as a voltage. The value was multiplied by the gain of 30.58 and then the offset value of 24.46 was deducted. The final value was outputted to the screen as a percentage.

Temperature sensor input was obtained once every three seconds and stored in a circular queue controlled by two pointers. These values were accessed using the position of the pointers and their values plotted onto a graph.